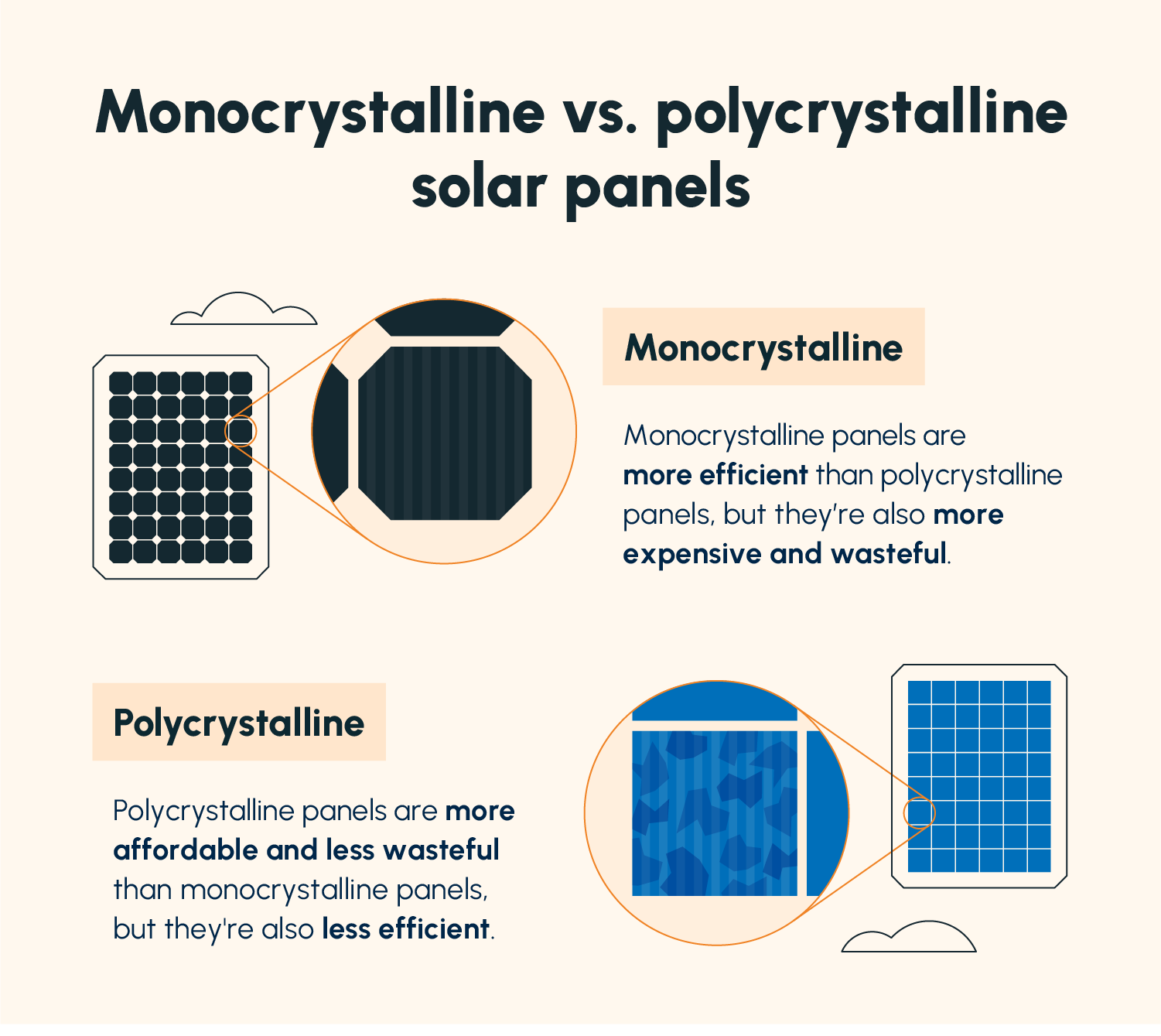

Monocrystalline solar panels are more efficient due to their purity — each cell is made with a single silicon crystal. Polycrystalline panels are less efficient since they're made with a blend of silicon crystals.

"Photovoltaic," "lithium-ion," "microinverter" — the world of solar panels is filled with a lot of technical terminology that would make any first-time solar customer rub their eyes. Our goal is to demystify these terms, and in this guide we'll be focusing on two important ones: monocrystalline and polycrystalline.

Don't panic — these terms are simpler than they sound. They're just used to describe two ways that solar panel cells are made. In this guide, we'll unpack monocrystalline vs. polycrystalline solar panels and guide you through the process of choosing one over the other.

What Are Monocrystalline Solar Panels?

Monocrystalline solar panel cells are created using a single silicon crystal. Since each cell is composed of one silicon source as opposed to many, these cells are purer than those of polycrystalline panels. This comes with some benefits and drawbacks for the end consumer.

For example, monocrystalline solar panels operate a bit more efficiently — particularly in hot temperatures — than polycrystalline panels. They also have a uniform black appearance that some solar customers appreciate.

That said, due to their purity, they cost more to produce. This added cost largely falls on the consumer, so be ready to pay a bit of a premium if you opt for monocrystalline panels. Unfortunately, these panels also involve a more wasteful production process — mono cells are cut in an octagonal shape (to fit more cells), meaning extra silicon is shaved off.

Pros:

- Higher efficiency

- Better heat resistance

- Uniform, black appearance

Cons:

- More expensive

- More wasteful production process

What Are Polycrystalline Solar Panels?

Polycrystalline solar panel cells are made with a blend of silicon crystal fragments, rather than with a single silicon crystal. Since it doesn't matter if you mix different sources of silicon together when making poly cells, the production process is less wasteful than that of mono cells.

That said, these panels do take a bit of an efficiency hit, particularly when they get hot. However, they cost less to produce and therefore cost the end consumer less — a tradeoff that many homeowners are willing to accept.

Pros:

- More affordable

- More sustainable production

Cons:

- Lower efficiency

- Poorer heat resistance

- Blue color that grabs attention; imperfections visible up close

Monocrystalline vs. Polycrystalline: Key Differences

Let's take a closer look at how monocrystalline and polycrystalline solar panels compare with regard to the following qualities.

|

Monocrystalline |

Polycrystalline |

|

|

Price |

Higher price tag |

Lower price tag |

|

Efficiency |

Slightly higher |

Slightly lower |

|

Heat resistance |

Slightly higher |

Slightly lower |

|

Appearance |

Black and uniform |

Blue and uneven |

|

Sustainability |

Wasteful production |

Sustainable production |

Price

Monocrystalline solar panels tend to fall somewhere between 10-30% more expensive than their polycrystalline counterparts.

To create polycrystalline cells, manufacturers melt down silicon from multiple silicon crystals and pour this mixture into square molds, which are then cut into cells. This strategy is far simpler and less labor-intensive than the careful solidification and cutting of monocrystalline cells, which explains the higher price point of mono panels.

Efficiency

Monocrystalline panels can reach efficiencies upward of 23%, whereas most polycrystalline panels have a cap of 20% efficiency. Monocrystalline solar panels operate at a higher efficiency than polycrystalline panels, as electricity can flow more seamlessly through cells composed of the same silicon crystal than those composed of a blend of many crystals.

Heat Resistance

The same logic applies to mono vs. poly solar panels' heat resistance. Monocrystalline solar cells' electricity-generating efficiency isn't as negatively impacted by high temperatures as solar cells composed of blended silicon are. If you live in a region that gets really hot, mono panels are the best option.

Appearance

Monocrystalline panels are black, have octagon-shaped cells, and few visible imperfections. Polycrystalline panels are blue, have square or rectangular-shaped cells, and may have some visible imperfections due to the blend of silicon crystals. That said, beauty is in the eye of the beholder — choose whichever panels you like best!

Sustainability

When it comes to producing each type of panel, there's more waste involved when with monocrystalline panels. The process of cutting monocrystalline cells results in quite a bit of silicon waste, whereas polycrystalline cells don't waste silicon since each cell is composed of mixed silicon.

Regarding longevity, both panel types last over 25 years on average, with monocrystalline panels just outperforming polycrystalline panels. However, the difference is relatively negligible.

Other Solar Panel Tech Terminology to Know

Monocrystalline and polycrystalline aren't the only two technical terms for solar panel technology that you should know. Here are some other types of tech you might see in product descriptions as you shop around.

N-Type vs. P-Type Solar Cells

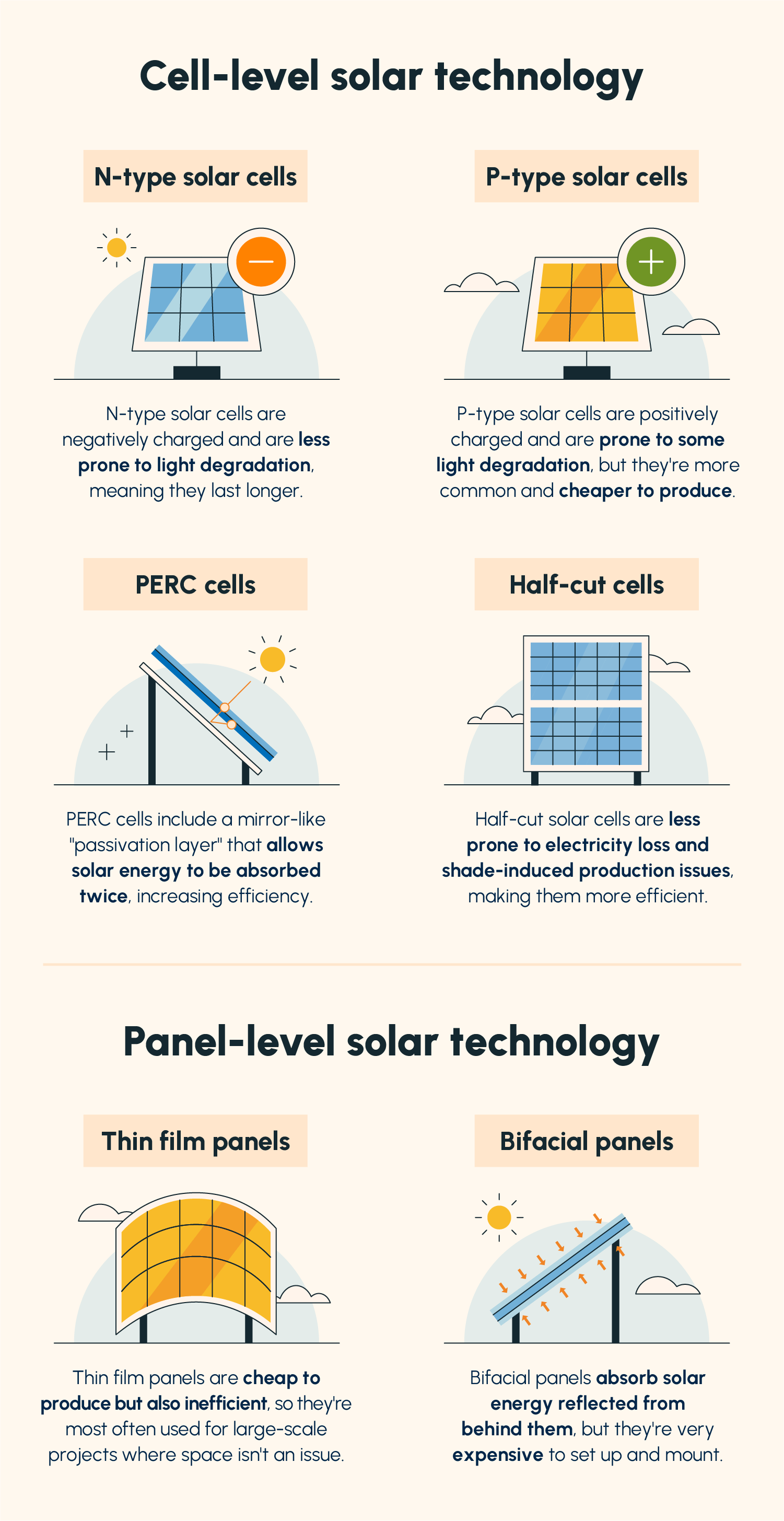

Silicon wafers can be treated in different ways to make functional solar cells, which is where we get N-type and P-type cells.

- N-type: N-type cells are created by doping silicon wafers (adding impurities to modify their conductivity) with phosphorus (which has one more electron than silicon), negatively charging the cell. They are not prone to light-induced degradation (LID), meaning they tend to maintain their performance over long periods of time.

- P-type: P-type cells are more common than N-type cells. They're created by doping silicon wafers with boron (which has one less electron than silicon), positively charging the cell. These cells are prone to LID, so they wear out slightly more than N-type cells over time.

Despite the slower degradation of N-type cells, panels made with them tend to be priced at a premium and many solar customers do not consider the benefit to be worth the added investment.

PERC Cells

Passivated Emitter and Rear Contact (PERC) cells are a technology used to enhance solar panel productivity. PERC cells include an added layer on the backside of solar panels (known as the passivation layer). This layer reflects light back to the panel, giving it another chance to absorb solar energy, increasing the amount of electricity it produces by 6-12%.

PERC technology is becoming highly popular since it adds a lot to solar panel efficiency and doesn't cost an arm and a leg to produce, unlike some other technologies that provide slight efficiency boosts.

Half-Cut Cells

As the name suggests, half-cut cells are solar cells that are cut in half. This practice is primarily used to improve cell performance.

First and foremost, half-cut cells are more efficient than traditional solar cells. Some electrical current is lost as it travels between traditional solar cells due to resistance. But cutting cells in half also halves their electrical current, which results in less resistance and, therefore, less electricity loss.

Half-cut cells can also perform better in shade. With traditional panels, if one cell is shaded, the entire row of cells also gets affected. Since half-cut panels have double the number of rows of traditional panels, shade on one cell only affects half the number of cells it would in a traditional panel.

Thin Film Panels

While most solar panels (and nearly all residential panels) are monocrystalline or polycrystalline, another type — known as thin film panels — frequently get used for major utility projects and mobile uses. While they're the least expensive panels money can buy, they're far less efficient than both monocrystalline and polycrystalline panels, making them a poor choice for homes with limited space for solar.

Unlike other types of panels, they're created by simply adding a thin layer of conductive material (usually a silicon film) to a backing plate made of glass, plastic, or metal. They can be really flexible, which is why they tend to be used for RVs and boats.

Bifacial Panels

Bifacial solar panels have conductive material added to both their front and back sides. The aim of these panels is to capitalize on reflected sunlight that reaches the back of the panel.

Unfortunately, these panels require a really expensive mounting setup — one that provides enough space below the panels for light to reflect and includes a reflective material (usually something white in color) on the surface under the panels.

As a result, despite some efficiency gains, bifacial solar panels rarely justify the added cost of installation. That said, it's a tech to look out for in the event that less expensive mounting options become available.

How To Choose the Right Solar Panels

Whichever type of solar panel you choose, you'll be glad you made the transition to renewable energy. Still, there are a few factors that might influence you when choosing between monocrystalline and polycrystalline panels, outlined below.

Cost

Typically, monocrystalline panels cost more than polycrystalline panels. That said, an easy way to make sure you're getting the best bang for your buck is calculating each individual panel's cost per watt. Just take the panel's price and divide it by its advertised wattage. If you notice a significant difference in cost for comparable technology, go for the cheaper option.

Available Space

The less space you have available for solar panels, the more important panel efficiency becomes. If you want to keep all of your panels on your roof but don't have much optimally positioned roof space, you may opt for the more efficient monocrystalline panels.

Personal Preference

Ultimately, your decision comes down to personal preference. You may trust some manufacturers — or countries of manufacture — more than others, or you may have an appearance preference. Mono and poly panels have pretty different appearances, and one may look better on your specific roof than the other.

Monocrystalline vs. Polycrystalline FAQs

Solar panel technology can get, well, technical. Below, we answer some common questions about monocrystalline and polycrystalline solar panels.

What Is Better: Monocrystalline or Polycrystalline?

While monocrystalline solar panels perform more efficiently than polycrystalline panels on average due to their purity, polycrystalline panels still perform very well and come at a lower price point. Overall, there is no objective winner, and the better option depends on each individual's personal priorities.

Can You Mix Mono and Poly Solar Panels?

Combining mono and poly solar panels in the same system shouldn't pose any issues as long as your panels' specs (especially relating to electrical current) are the same or very similar. That said, it's best to stick to one to avoid any potential complications.

Are Monocrystalline Solar Panels the Best?

Monocrystalline solar panels are typically more efficient, perform better in high temperatures, and may last slightly longer than polycrystalline panels. That said, these differences can be marginal, so it's not recommended to rule out polycrystalline panels, especially if you're looking to cut your costs.

Ultimately, whichever type of panel you choose, Solartap partners with brands that create the best solar panels on the market. Explore our selection today or get a quote using our solar calculator.